Agglomerator machine is used to convert film wastes (loose plastics) into plastic chips suitable to be fed the hopper of extruder.

In the agglomerator machine ,There is heavy duty mild steel rotor fitted on the center of the agglomerator drum. Rotor has 4 en series hardened blades fitted. Six blades are fitted on the inside diameter for agglomerator drum at symmetrical distance. The blades are made from special EN series mild steel with hardening process. Heavy duty bearing housing provided for shafting. AC motor is connected with shaft. Adjustable motor attachment provided. Output mouth provided with handle and open/close system.

In the entire process, A plastic material, normally in wastage form (film waste) is dropped into agglomerator feeding spot , reach the rotor whilst rotor is in rotating condition. Blades cut the film plastic constantly which creates friction and heat until it reaches the desired size. This process causes material to reach to the softening point. In this stage, operator add some water to create a kind of shock. After water evaporates, material comes out from discharge spot as chips.

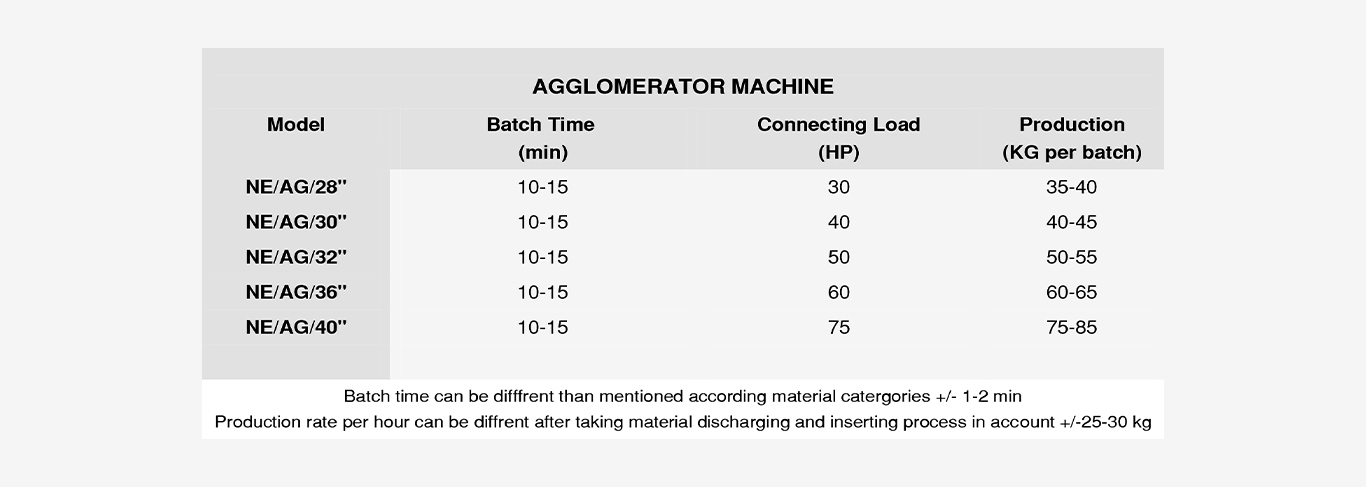

various models available which are classified according their blade size and production rate. 28 inch to 40 inch models available.

Production Range of 100 kg/hr to 350 kg/hr.

Heavy duty bearing housing provided for sturdy operation and longer life.

EN hardened series material blades provided.

Heavy fabricated channel stand to be provided for vibration free performance.

Simplified discharge system to discharge raw material to be provided for simple operation.

Driven by Reputed brand motor.

Easy to operate.

Less Maintenance.

Thermocouple sensor to monitor the temperature of the drum.

Auto on/off system according batch time with buzzer

Pneumatic system at discharge spot.

Stainless steel coating inside drum.