Rotomoulding, also known as rotational moulding, is a plastics moulding technology which is ideal for making hollow articles. It is a casting technique but unlike most other plastics processes there is no pressure involved.

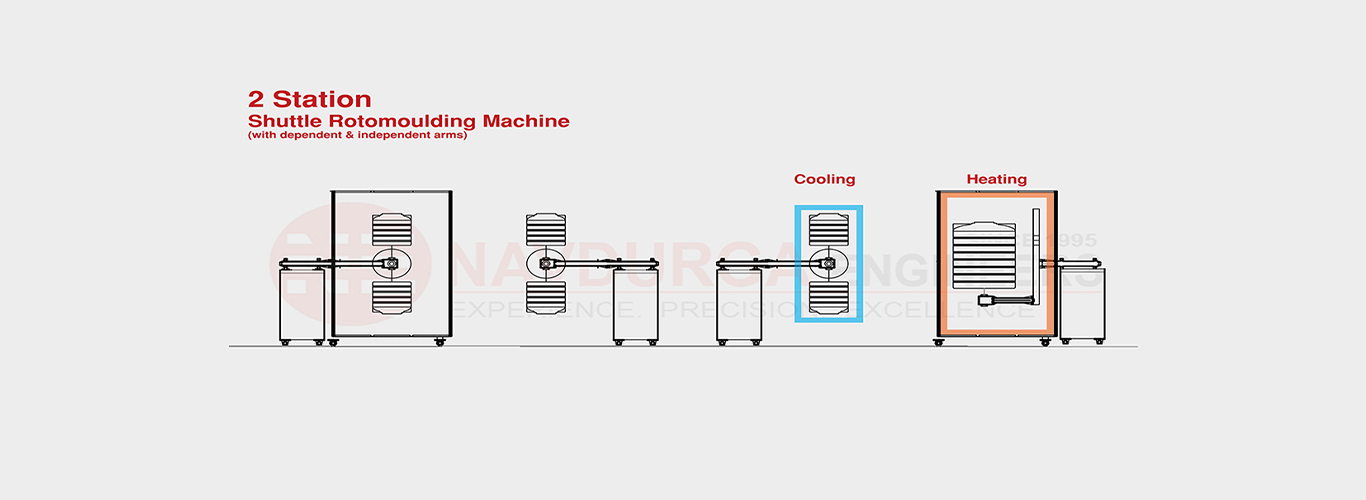

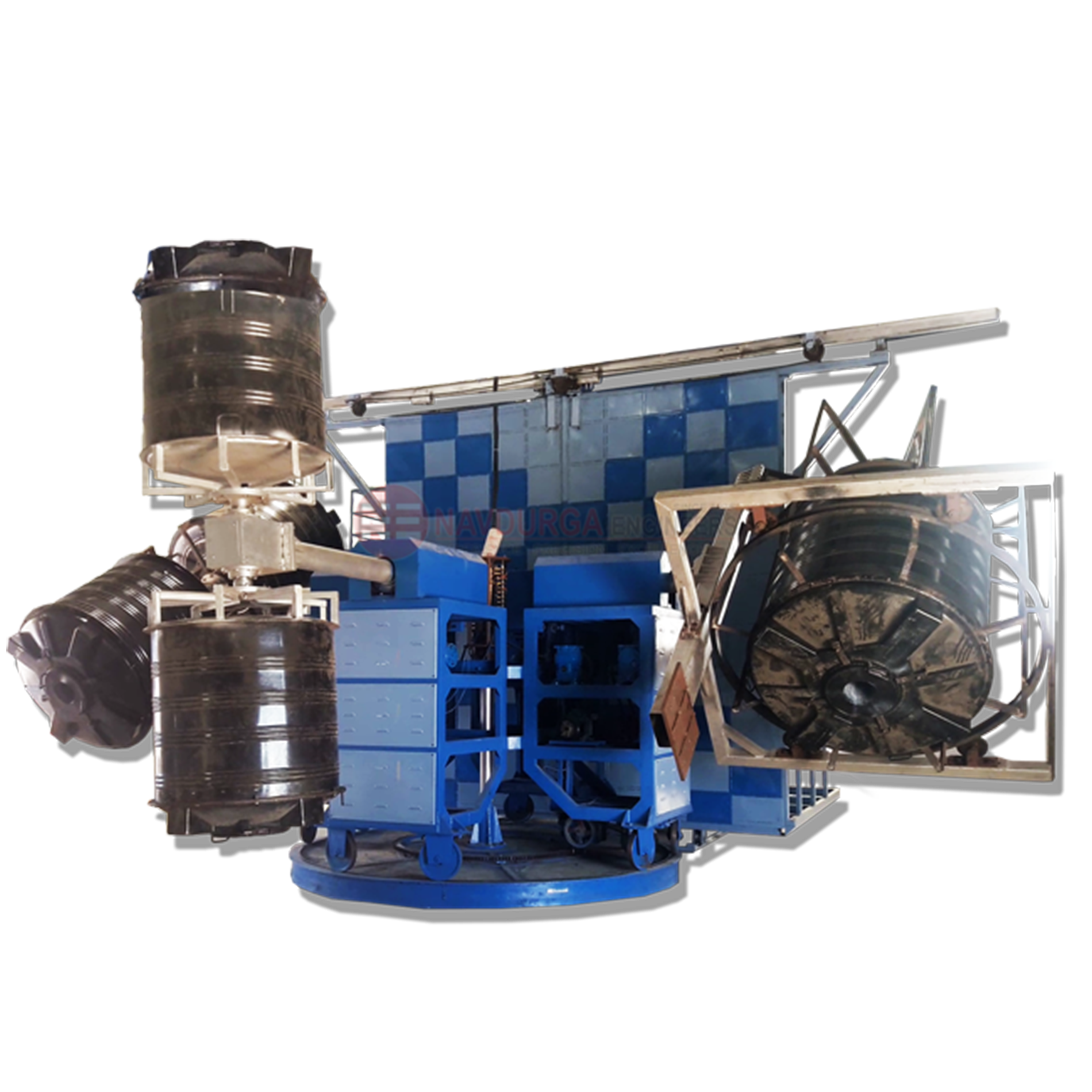

In the entire process, A plastic material, normally in powder form is placed into a hollow mould, usually made from fabricated from mild steel or fabricated from stainless steel. The mould is closed and rotated on arms. The mould is then heated in an oven whilst rotating and the polymer gradually melts and ‘lays-up’ on the inside of the mould. Once the polymer powder has fully melted the mould is moved to a cooling station and cooled usually with air and sometimes a fine mist of water. As the mould cools the part solidifies. When the material has finally cooled sufficiently to release away from the mould surface. Arm moves to the unloading spot and the product is taken out of the mould & then again reloaded for the next cyclic process.

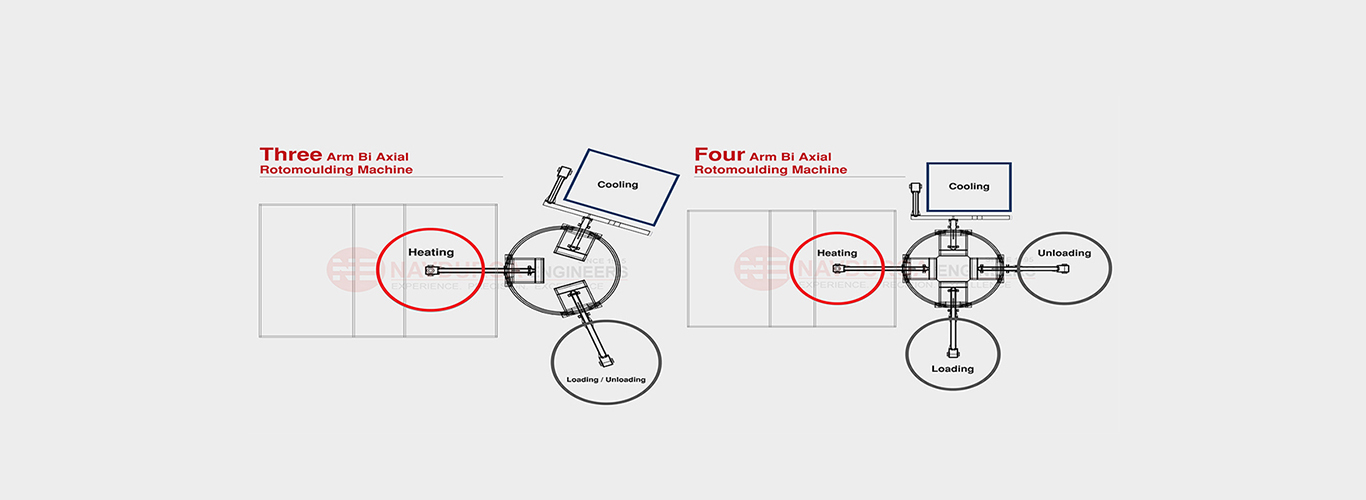

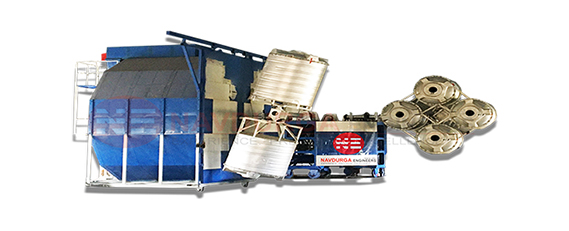

Meanwhile in four arm bi axial rotomoulding machine, cycle runs constantly. If one arm is in the oven for heating, second arm will be on the cooling station, third arm will be on the unloading spot and forth will be on loading spot. Graphically explained in the layout.

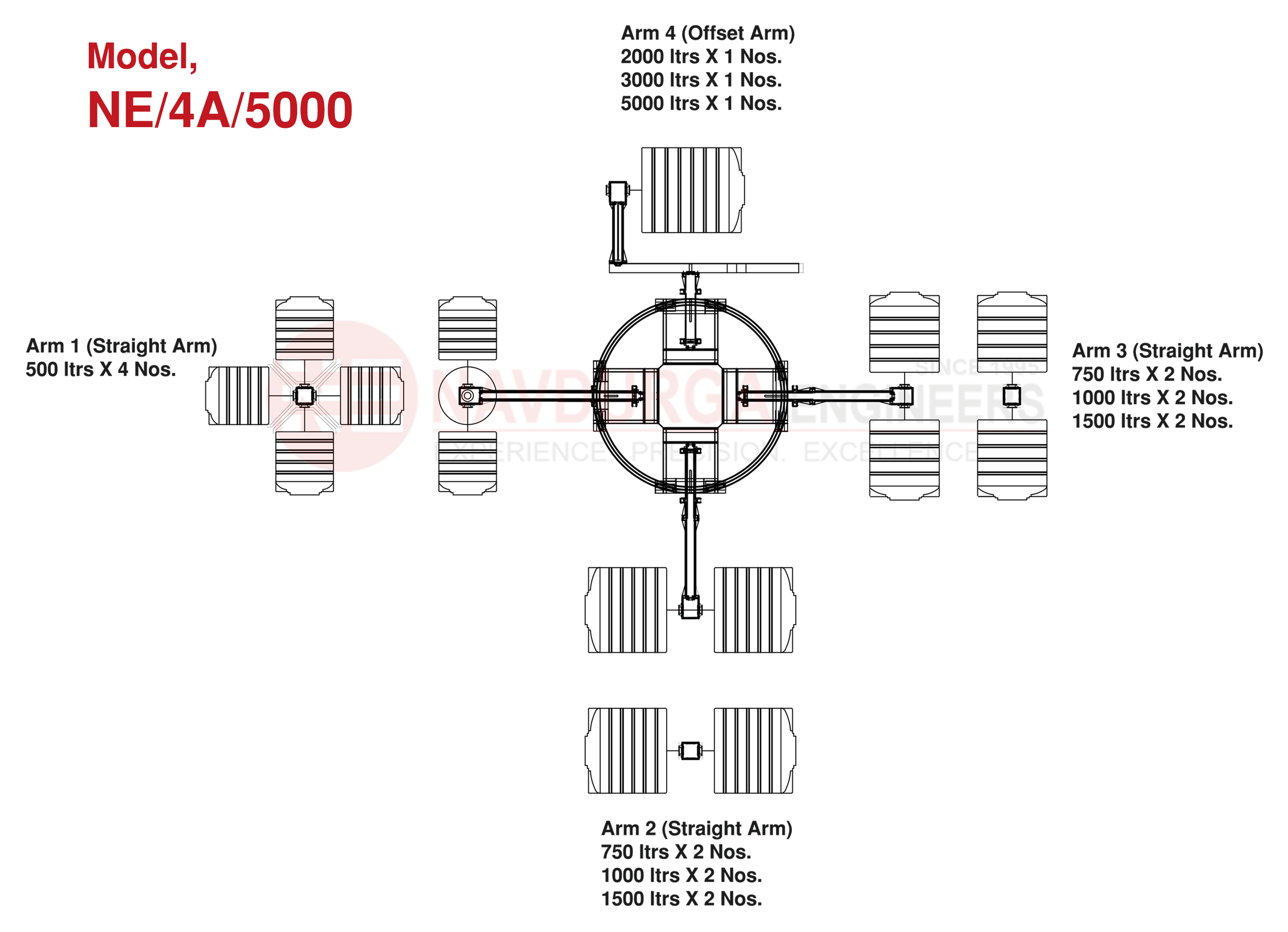

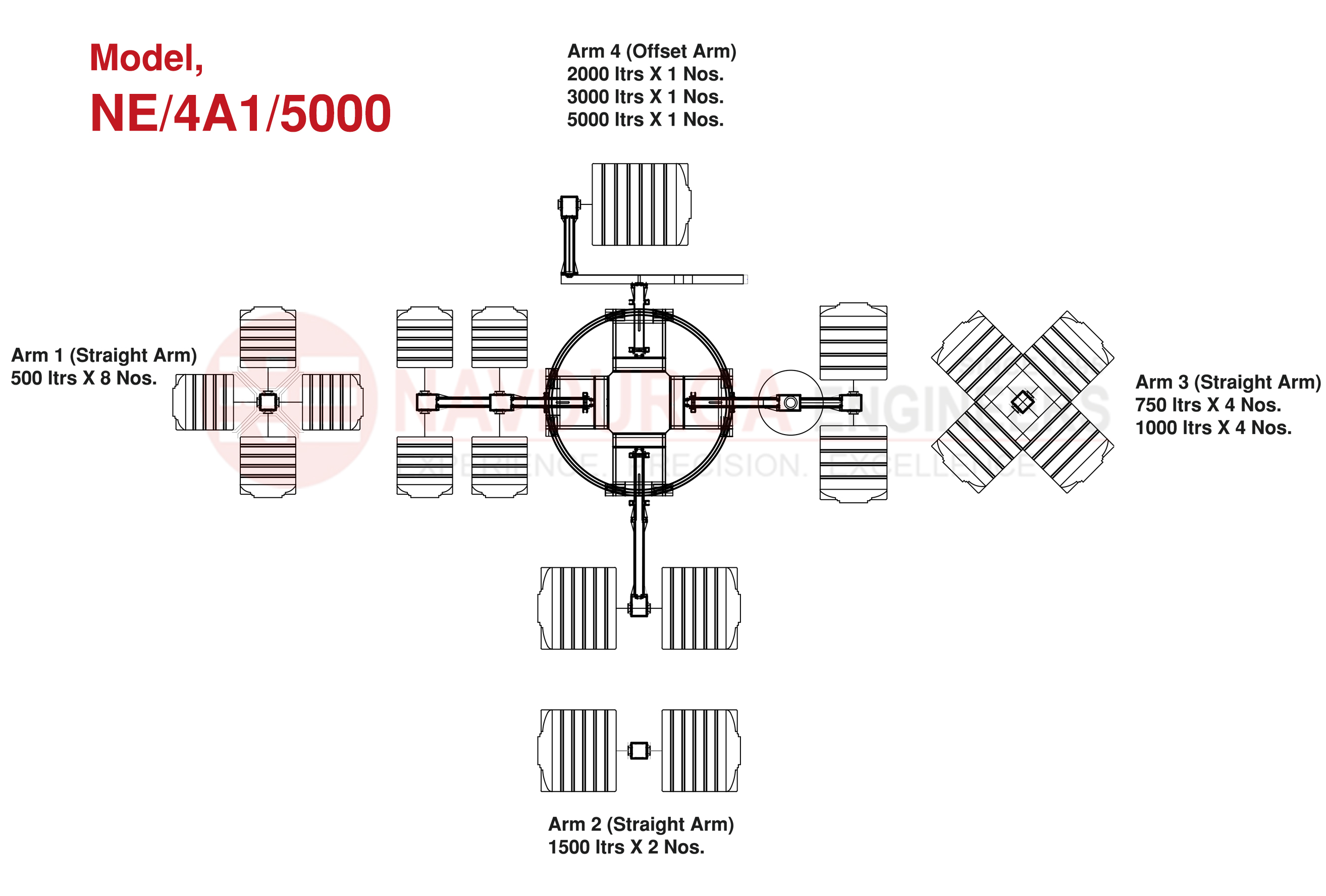

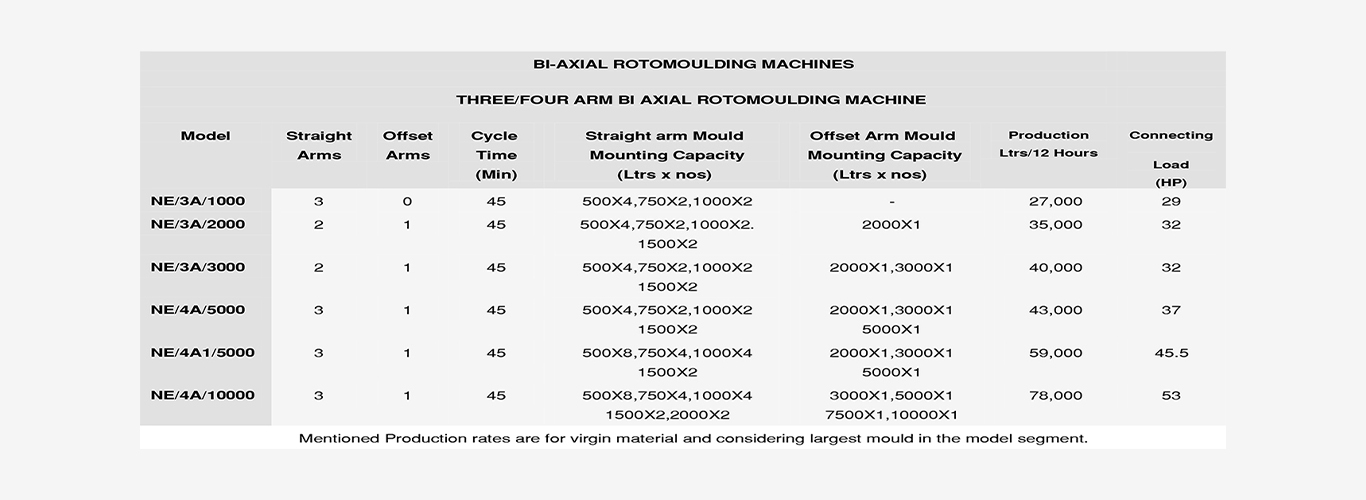

Various Models Available, which are classified according production rates and mould mounting capacity. Four Arm Bi Axial Rotomoulding Machines : NE/4A/5000, NE/4A1/5000, NE/4A/10,000 Three Arm Bi Axial Rotomoulding Machines : NE/3A/1000-2000-3000-5000 etc. These machine models are customizable, where client can choose amount of arms (max 4) and mould mounting options according their requirements.

Maximum Production Capacity Upto 10,000 ltrs in a single time.

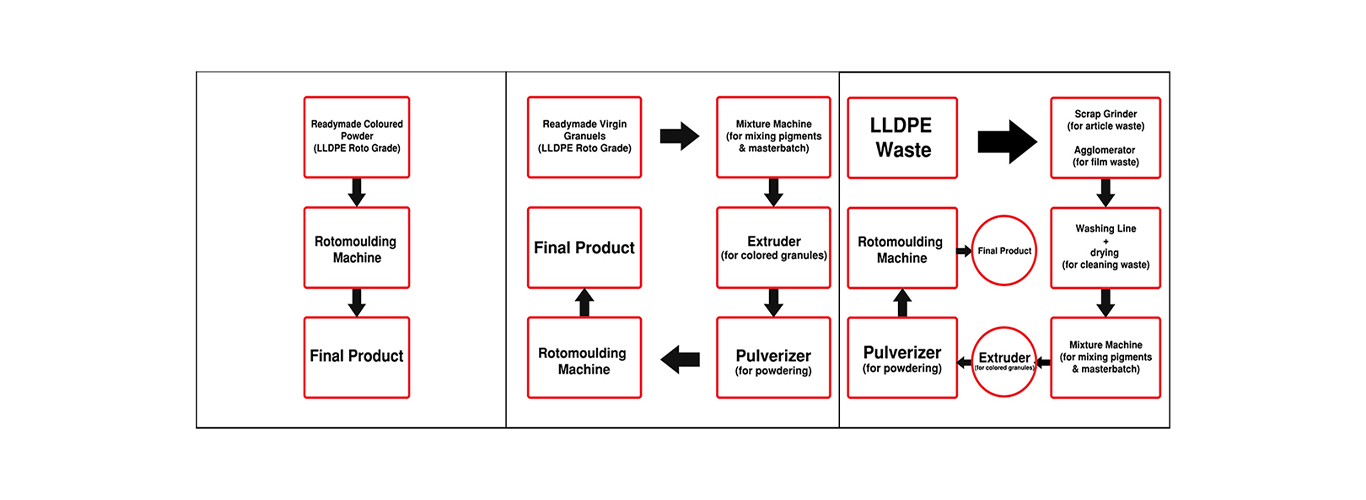

Entire rotomoulding project available Machineries which can convert plastic waste into plastic

Water tank or any hollow article. List of machineries are as mentioned below,

Scrap Grinder Machine / Agglomerator Machine

(To Convert plastic waste into small sized flakes)

Automatic washing line

(To wash and dry plastic flakes / clean the dirt out of flakes)

Mixture Machine

(To add pigments/masterbatch with the washed flakes for coloring purpose / To heat up the flakes for removal of all possible moisture out from the flakes)

Extruder machine

(To produce granules out of the flakes / For coloring granules with the desired color)

Pulverizer Machine

(To make powder of the plastic granules for moulding purpose)

Moulds (Different shape of moulds manufacturing capacity)

Most efficient in fuel & energy consumption compared to other types of machines.

Uniform heating of the mold with forced air circulation and smooth Bi-axial rotation produce

finish product quality.

Highest production due to lowest cycle time.

Uniform distribution of material hence possible to produce article with lesser weight.

Best compatibility in the market due to lowest production cost.

Lowest rejection rate due to sound & proven technology.

Energy efficient & environment friendly auto system Italian make burner.

Flexibility to produce double & triple layer upto six layer tanks due uniform distribution of material.

AC drives of reputed brands for all minor & major axis’s for accurate speed control.

Powder coated electrical control panel with dust proof construction & with all switch gears.

Control panel is equipped with AC drives, digital indicators, temperature controller, timer & advance automation circuit for entire process control & all necessary safety features.

Auto reverse forward panel for minor axis’s.

Optional attachments :

Powder loader machine (to fill up the mould with less efforts with use of powder loader) HMI based control panel (advance touch screen control system with automation facilities)

Lift (to travel quickly to the oven top for powder loading process)

pneumatic spanner along air compressors (to open/close moulds easily),