Suitability

Mostly suggested for virgin, next to virgin or plant waste materials. HDPE, LDPE, LLDPE, BOPP FILM and PP natural.

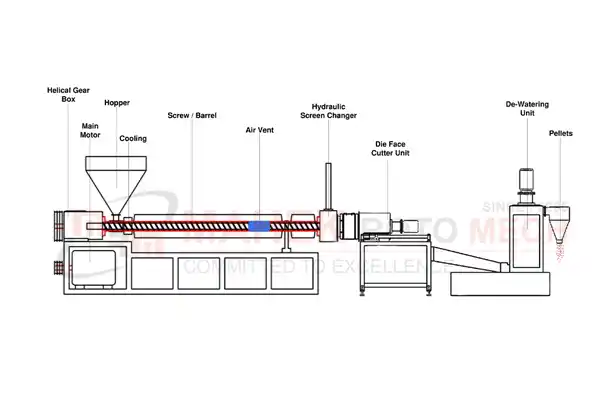

How It Works

In the entire process, A plastic material, normally in flakes form is placed into hopper of extruder, usually made from fabricated from mild steel or fabricated from stainless steel as per material requirement. There is a hopper magnet fitted inside the hopper to stop metallic particles from entering inside the barrel.

The raw material in the form of flakes, is gravity fed into the hopper and through the feed throat, drop on the rotating screw. Barrel has a air vent for degassing the material and machine contains the AC frequency drives to adjust the motor rpm. Barrel has several amount of heaters fitted on the outer diameter. Which heats up the barrel to get extrusion process job done. Screw is connected with helical gearbox and AC motor which helps to rotate the screw.

Raw material in flakes form starts to move forward along the rotating screw and enters the heating spot of barrel. Where it starts to melt. Molten plastic reaches the end of the barrel where hydraulic screen changer is fitted which filters the molten plastic and leads it to the die face cutting unit where sharp blade is rotating on high rpm on face of outer side backer plate of the screen changer.

This blades cuts the molten plastic into round shaped pellets. Entire cutting process occurs In presence of constant water circulation. Finished pellets travels to the de watering unit along water flow. In de watering unit, pellets get completely dry and travels to the storage silo with the help of hot air blower.

Production range

Production Range of 100 kg/hr to 250 kg/hr.

Salient Features

- Screw & barrel are made of EN41-B mild steel, nitride and honing finished for quality production & longer durable life.

- Optional : Tungsten carbide coated screw & barrel available, for high production machines to provide a longer durable life.

- Barrel has a air vent on outer diameter for degassing of the material processing inside.

- Screws are designed for specific material to get better quality for specific material while producing single category material or universal design for every material.

- Barrel has been divided into heating zones for accurate temperature control.

- Digital pyrocontrol panel for faster heating & energy saving.

- Thermocouples are provided for each heating zones for temperature control through digital temperature controllers.

- Movable motor attachment provided for main AC motor.

- Extruder unit is consisting of heavy & sturdy MS channel’s fabricated frame and covered with CRC sheet.

- High efficient hopper magnet provided for detect and restrict the ferrous material from the polymer.

- Screw is rotated by suitable AC motor along AC drives with heavy duty helical gear box. AC motor and helical gear box are from reputed brands.

- AC drives are used to adjust the speed of motor according material requirements.

- Hydraulic screen changer provided to filter molten plastic in case it contains dust or particles. Die attached with hydraulic screen changer which leads molten plastic into die face cutter unit. Comes along power pack.

- Die face cutter unit is fabricated with SS 304 material. Carbide blades fitted on rotating shaft near the outer edge of screen changers backer plate.

- Die face cutters shaft connected with AC motor and AC drive from reputed brands.

- Water supply system provided for smooth cutting process for die face cutter unit.

- De watering unit provided to remove moisture from the surface of finished pellets as die face cutting process entirely occurs in presence of water flow.

- De watering unit is completely fabricated from SS 304 and contains AC motor from reputed brand.

- Water pump to be provided with AC motor.

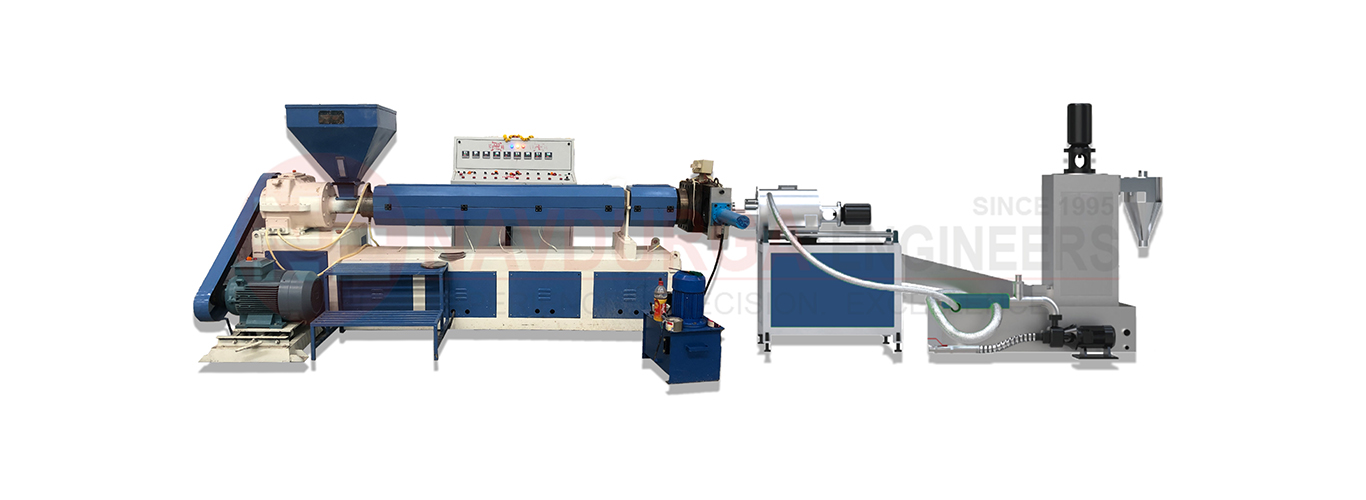

Layout