Plastic Pulverizer

We have been able to cater to the various requirements of clients by providing a wide array of Pulverizer. Pulverizer is used to turn plastic granules and plastic flakes into plastic powder. Plastic powder is used in various plastic finished manufacturing industries like water tank, pipe & profiles etc.

How It Works

In the entire process, A plastic material can be in granules form (for lldpe) or in flakes form (for pvc) is placed inside the hopper of pulverizer machine, the raw material starts to feed inside the housing of the pulverizer machine. The housing contains one set of blade, which blade is made of special material which gets the job done. Plastic granules enter in the housing and collected in the center of the grinding disc. It is then pushed outwards by the centrifugal force between stator and rotary disc. Powder form of the material comes out of the housing with the help of blower which cools powder intensively and enters in the vibro shifter. Vibro shifter differentiate the powder uniformly and separate the unsuccessful grinded particles into different container which can be used for regrinding.

Model Range

The blade size and motor of pulverizer machine causes the difference between each model with different production rates. 400 to 600 mm blade sizes are available for pulverizer machines.

Production range

Our Plastic Pulverizer Models have Capacity of 50 kg/hr to 300 kg/hr.

Salient Features

- Complete robust & very sturdy structure for sound and vibration free operation.

- Magnetic type vibrating feeder for uniform and controlled feeding of material.

- Main grinding disc made from superior grade material for longer life.

- Very effective water cooling system with jacketed arrangement.

- Vibratory screen for fine re-pulverizing of course material.

- Main shaft made from special hardened steel and dynamically balanced.

- Powder coated electrical control Panel with all safety features & major switch gears of M/s L&T or reputed make.

- All mechanical components and electrical accessories are of reputed & reliable make.

- Complete design with flexibility & perform fine pulverizing of wide range of plastics material like LLDPE, LDPE and PVC other heat sensitive material.

| PLASTIC PULVERIZER MACHINE | |||

|---|---|---|---|

| MODEL | BLADE SIZE(mm) | CONNECTING LOAD (HP) | PRODUCTION(KG/HR) |

| NE/400/PUL | 400 | 30 | 100-120 |

| NE/500/PUL | 500 | 40 | 150-175 |

| NE/600/PUL | 600 | 50 | 180-250 |

| Mentioned Production rate is for virgin material | |||

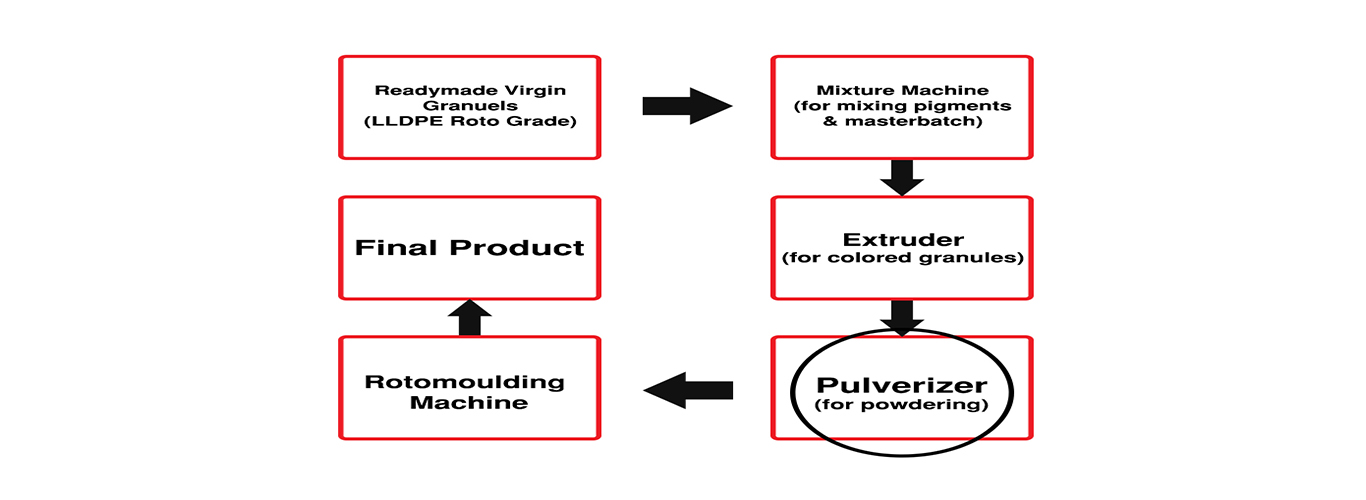

Process Flowchart: